Your modern Renault vehicle is packed with advanced electronics which are designed to make your driving experience reliable, comfortable, enjoyable and safer. In fact, most of the time you probably do not even know they’re are hard at work and take them for granted. These electronics monitor and control pretty much every function of your world whilst you are driving and in some cases take many readings in a single second! From the simple systems such as the electric windows, central locking, exterior lighting, signals and the exterior temperature display to the far more complex safety system features such as anti-lock brakes, stability control, vehicle security and fuel injection. When something goes wrong with one of these systems you need accurate fault finding, more commonly referred to as “diagnostics” and fast but this is an area in the trade which can be a frustrating and expensive headache for you, the customer.

Your modern Renault vehicle is packed with advanced electronics which are designed to make your driving experience reliable, comfortable, enjoyable and safer. In fact, most of the time you probably do not even know they’re are hard at work and take them for granted. These electronics monitor and control pretty much every function of your world whilst you are driving and in some cases take many readings in a single second! From the simple systems such as the electric windows, central locking, exterior lighting, signals and the exterior temperature display to the far more complex safety system features such as anti-lock brakes, stability control, vehicle security and fuel injection. When something goes wrong with one of these systems you need accurate fault finding, more commonly referred to as “diagnostics” and fast but this is an area in the trade which can be a frustrating and expensive headache for you, the customer.

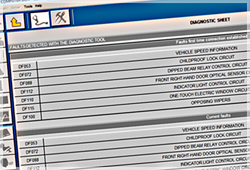

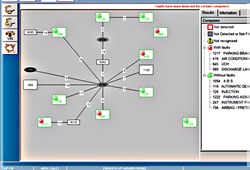

The real dilemma – Who can you really trust? Everyone appears to be an expert with their impressive looking workshops and expensive hi-tech pieces of computer equipment that claim to deliver everything and fast. Looks however can be deceiving along with the actual ability of the ‘generic’ equipment and that’s not to mention the experience and technical ability of the operator either. Most of the ‘generic’ equipment available to the Independent garages today does the basics very well but they always seem to fall short of the mark and cannot always access the full array of the networked systems that reside in your vehicle. Where some are clearly better than others and can access in depth systems others simply do not know what they’re seeing so cannot report any explanations or what the actual problem is and this is where problems can occur as it is incorrect diagnosis based solely upon on guess work that leads to the replacement of a costly part which you didn’t actually need. For this very reason, and to avoid making other costly mistakes we employ the very same equipment from SPX which is used in the franchised main dealer network allowing us to give you the same powerful, accurate results but at a far lower cost.

We are fully Renault repair manual process compliant and fully trained to use the equipment on systems such as:

We are fully Renault repair manual process compliant and fully trained to use the equipment on systems such as:

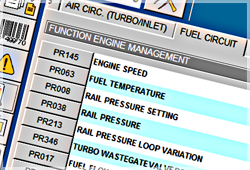

- Fuel injection: Petrol, Diesel, LPG

- Vehicle security & comfort: Alarm & Immobiliser, A/C & Climate control, Power steering, Instruments

- Anti-pollution: Fuel additive systems, Catalytic converters, Particulate filters & regeneration

- Safety features: ABS, SRS Airbags & Pre-tensioners, Traction control, Stability control

- Network & infrastructure: CAN Bus & K-Line networks, Body control/UCH modules

(images above show some examples of the data available in our diagnostic software)

A brief history of Renault Diagnostics and Technology

Most Renault’s made since the early 90’s usually had either a 12-pin or, from ’95 onward a 16-pin male J1939 socket hidden under the dash somewhere more commonly referred to as an “EOBD port” or “Diagnostic Port”. Vehicles and there control systems have come a long way since then and even in such a short space of time (over the last 10 years) the current models now utilise a “CAN-Bus” multiplex system. Very similar to the older “K-Line” setup except it is now a complex digital system that significantly reduces wiring requirements to just a single pair of cables which is all that’s required to carry streams of data to control and operate many different functions of your vehicle at the same time. Because of this the average mechanic cannot perform their job as effectively without some very pricey equipment. “CAN-Bus” was introduced by Bosch and is now an international standard (ISO 11898) on all modern vehicles. It is also worth noting that whilst generic code readers are becoming more affordable to the general public the process more commonly referred to as “Code Reading” is not performing a correct and full diagnostic and any garage or individual that does this and replaces parts based on a code reading session is more than likely going to fail to correctly identify and fix a problem or the equipment will simply not be up to the task of initialising or adapting the new components.